BUILD YOUR OWN WALK-IN COOLER

If you want to be able to deliver the freshest produce you can, then a walk-in cooler is a necessity. Commercially marketed coolers can be very expensive. However, you can construct your own walk-in cooler at a fraction of the cost.

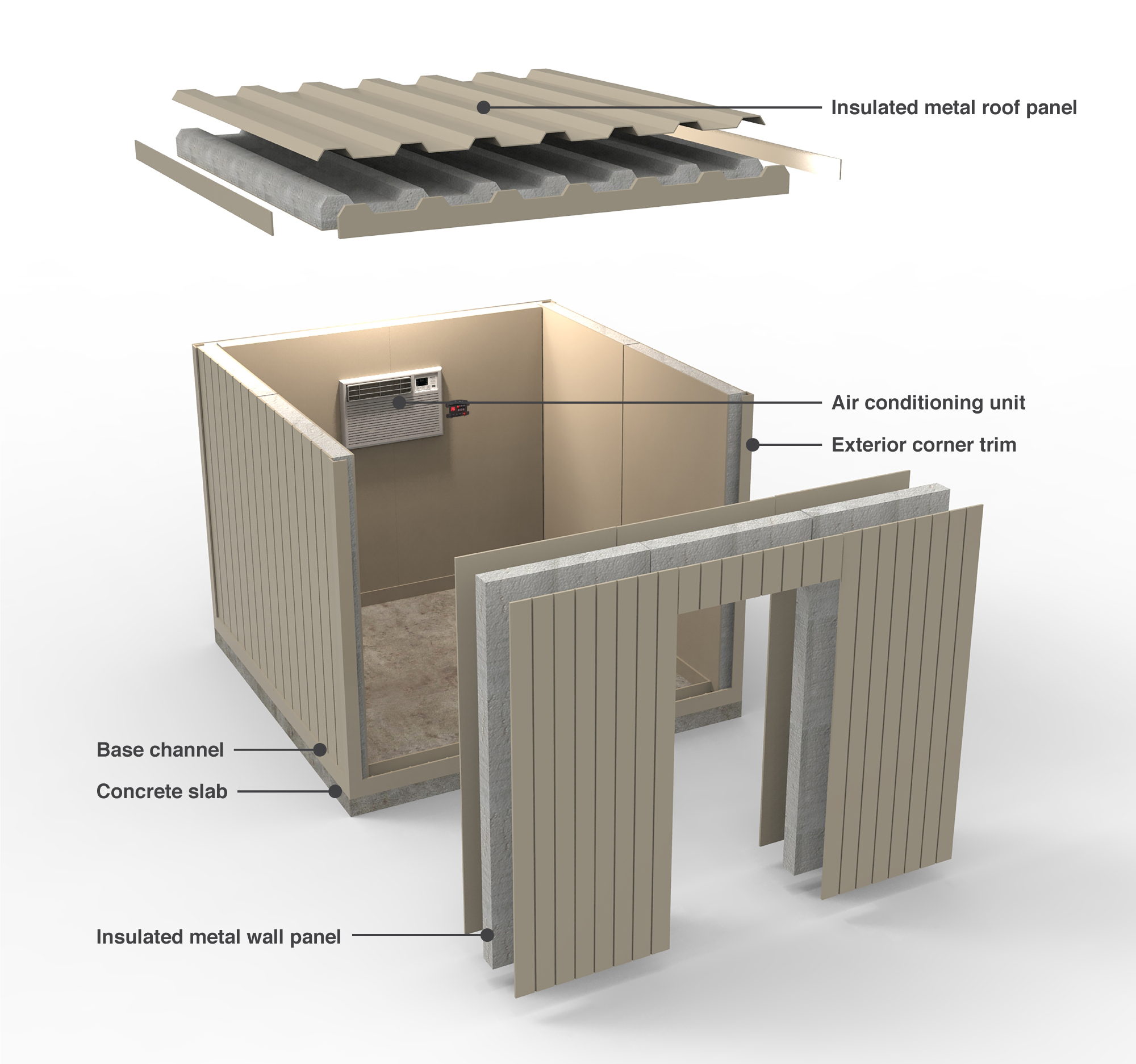

Insulated metal panels (IMP’s) are the most cost-effective, durable materials for your DYI Insulated cooler. They are also the easiest to install. This walk-in refrigerator is built with a normal window AC unit as the cooling system. A “CoolBot” is installed in the unit: a small robot that essentially runs the AC unit in overdrive, so that the cooling space is able to drop to temperatures much lower than the A/C would normally allow, to around 30-40 degrees F.

The basic IMP wall module is 39” wide, so for ease of installation and economy, dimensions should run in multiples of that dimension. Allow for overlapping panels in one direction. BASIC COOLER DIMENSIONS: 9’9” W X 7’6” D X 8’ H (6” thick panels)

The cooler is basically a large box with lots of insulation and a window-sized hole that fits the A/C unit. Preferably, you want to build this on a concrete slab or on EPS insulated wood floors.

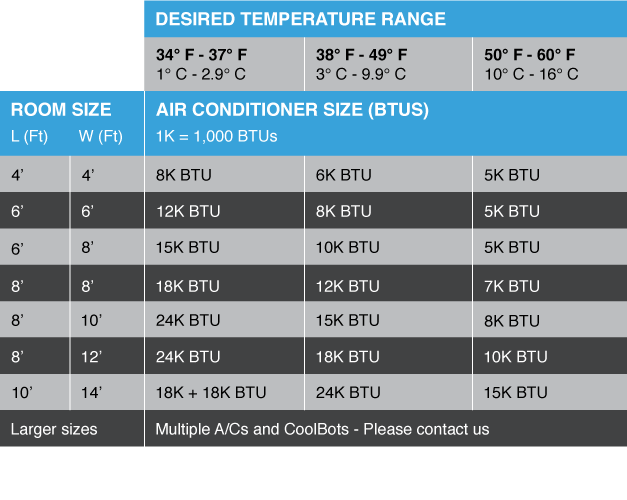

AIR CONDITIONING REQUIREMENTS

The CoolBot system requires that correct A/C capacities are chosen, according to the cooling necessities of your product. Window units are the best suited, but they can also fit into split units. Here are the recommendations:

BEST RECOMMENDED BRAND: LC ELECTRONICS

(UNITS RUN FROM $360 TO $800)

Some additional brands, such as Samsung, work well. Some models from Frigidare and GE work, but we recommend additional confirmation from the CoolBot manufacturer. It is important that the chosen unit has an automatic restart function in case of an electric failure.

SIZE THE COOLER WITH ROOM TO GROW, BUT NOT TOO FAR IN ADVANCE

Growers should size a cooler based on the highest volume that they are harvesting during the cooling period. The second factor to consider is anticipated growth.

-

Consider three days worth of stored produce.

-

Consider how much you will expand production.

-

Consider some moving space inside the cooler.

If you build a cooler much larger than needed, you will pay to cool an empty space. It may be wiser to start smaller, save money for a few years, then expand when the time comes.

Example:

-

Determine daily production

If you harvest 25 units of 2’ X 1’ crates, it will take 50 cu.ft of space.

-

Multiply by 3 days

50 X 3 = 150 cu ft.

-

Multilply production increase for next two years.

150 X twice production = 300 cu ft.

-

Cu. Ft divided by unit height = square foots required. Add + moving space:

300/ 8 = 37.5 sq. ft + 6 sq. ft = 43 sq.ft. (6.5’ X 6.5’ cooler)

WHAT YOU GET WHEN YOU BUY AN IMP COOLER KIT FROM FPG

- 39” wide Insulated Metal Wall Panels – 4” thick

- 40” wide Insulated Metal Roof panels – 4” thick

- Base Channels

- Corner Trims

- Fascias

- Gutter channel

- Trims for A/C wall assembly

- Screws

- Doors with frame insulation

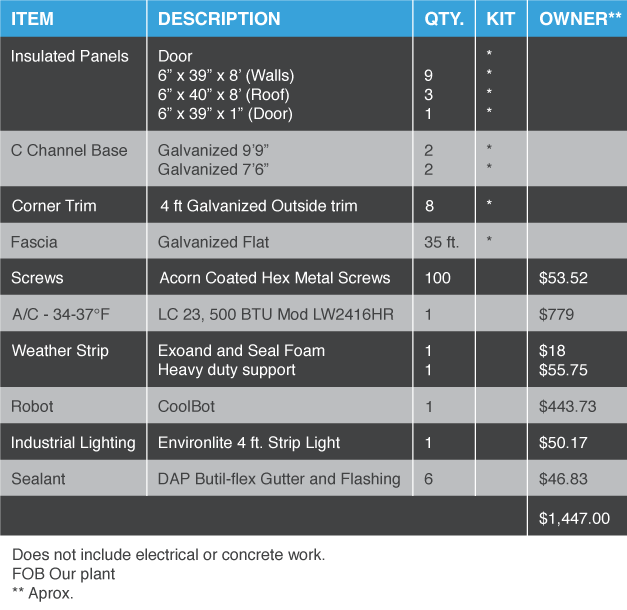

As the owner, you will need to acquire:

- An air conditioning unit w/ heavy duty support

- A CoolBot Robot (can be ordered through us)

- Sealant – preferably Butyl-flex

- Strip Lighting

- Foam Weather Strips

The owner will need to build an insulated concrete slab to exact cooler measurements. The additional slab will absorb heat and reduce cooling capacities.

If the cooler is built inside an existing structure, it does not need any additional insulation. All electrical wiring and connections are the responsibility of the owner.

Approximated cost of 9’9” X 7’6” cooler

Other Products

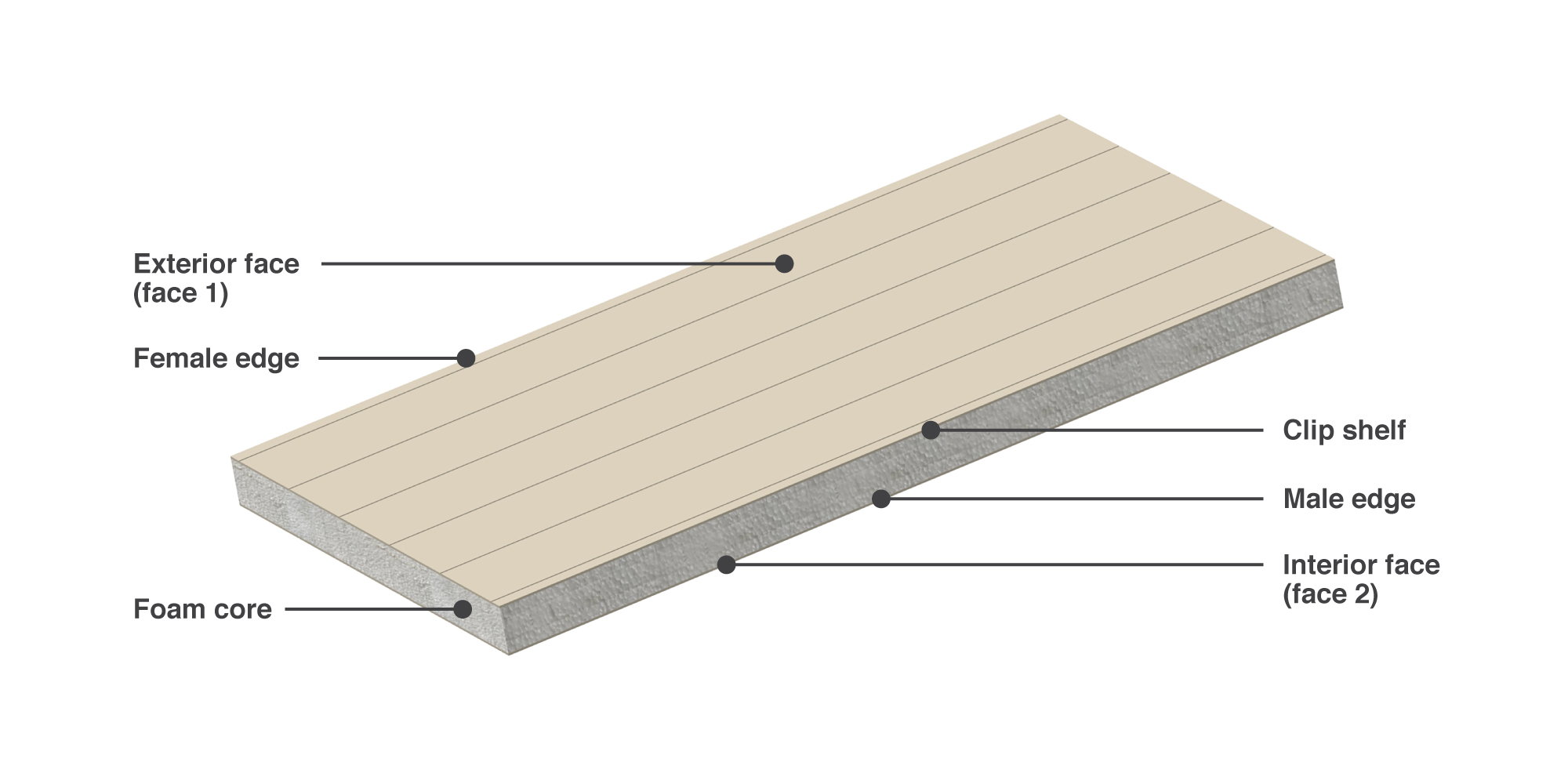

Sandwich Panel Wall

Our insulated metal panels are made of a special insulating foam that is sandwiched between two layers of metal. This allows your roof to maintain a more even indoor temperature, regardless of what is happening outside! It’s strong, cost-effective, and eco-friendly.

Sandwich Panel Roof

Our panels are so flexible that they can be molded to fit a wide variety of shapes and sizes. Steel or aluminum panel facings create vapor, air, and moisture barriers, minimizing maintenance every step of the way.

Formaletta Walls

Superior insulation, proven strength, easy installation and noise control are just a few of the benefits you get when you choose our insulated concrete forms. Take a look at this more efficient, more cost-effective alternative to conventional wood and concrete systems.

Custom EPS

We are here to make sure you get what you want. Didn’t see what you were looking for? We are happy to customize any of our paneling structures in order to best suit your construction needs.

Flepak Construction

Physical Address

Carr. 174 Km. 5.1

Bo. Guaraguao

Bayamón PR 00958

Mailling Address

P.O. Box 4321

Bayamon PR 00958-1321

Phone: (787) 506-2344

info@flepak.com